Rivets are structural elements used to connect flat elements, e.g. sheets and plastics. Due to the type of assembly, rivets are divided into: blind rivets and tubular ones with a core (blind). Capping rivets can be round, countersunk or cylindrical heads and made of steel, aluminum or non-ferrous metals. However, when it comes to blind rivets, apart from the standard ones, there are also e.g. tight, multigrip, structural, expanding - banana. They can be made of AL/ST (aluminium/steel), AL/A2 (aluminium/stainless steel), AL/AL (aluminium), St/St (steel), A2/A2 (stainless), A4/A4 (acid-resistant), Cu/St (copper/steel), Cu/Bronze (copper/bronze).

We also offer rivet nuts. They differ from blind rivets in that they have an internally threaded part. The advantage of rivet nuts is very quick assembly. We divide them into: through and non-through.

Blind rivets are used to connect and fasten metal elements. They are used in tinsmithing, aviation technology, heavy and light construction, with light metal building structures and protective installations. Round/counter head solid rivets are used in all metal structures for permanent connections, e.g. in steel structures of buildings, in the construction of cranes and bridges, in the construction of boilers, etc.

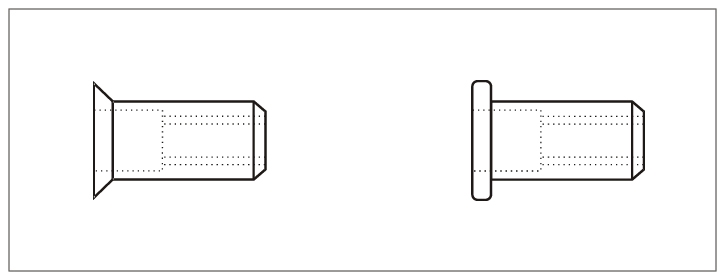

Types of rivet nuts:

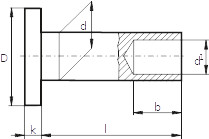

- cylindrical with cylindrical flange

- (enumeration from section V from the table of through and blind rivet nuts)

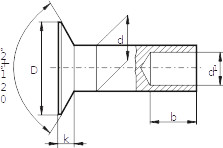

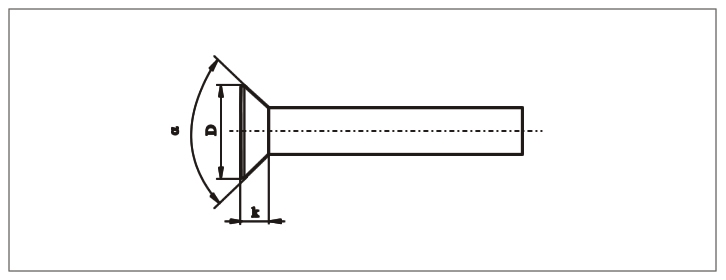

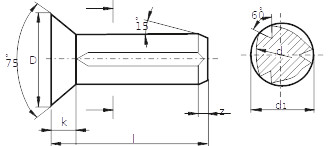

Countersunk head rivets

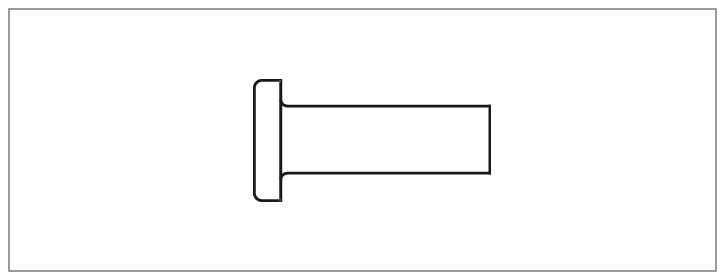

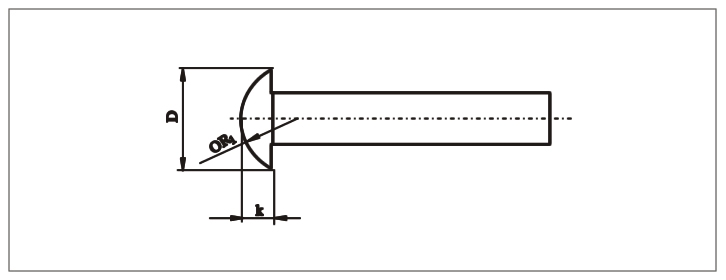

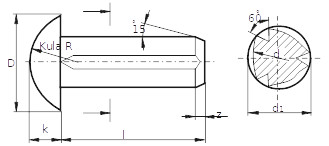

Round head rivets

Flat head tubular rivets

Rivet nuts with metric thread

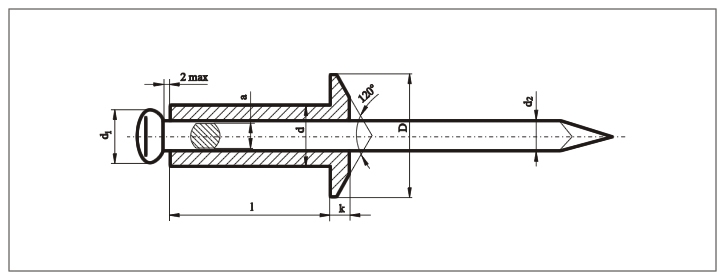

Countersunk head rivet pins

Round head rivet pins

Cylindrical head hollow rivets

Countersunk head hollow rivets