Cylindrical, conical and spring pins are used to maintain the exact position of the cooperating elements. They stabilize the position of a part or assembly of parts relative to another part or assembly of parts. Depending on the design requirements, they are pressed in with different interference. Tapered pins are more often used in multiple-separable connections because they are easier to assemble. In the event of anticipated difficulties with the disassembly of the connection (e.g. the need to knock out the pin from the blind holes), tapered pins with a threaded pin or with an internal thread are used, which allows the pin to be pulled out. Cylindrical pins are manufactured from stainless steel, hardened or heat treated. They are most often used in machine construction and, for example, in the automotive industry as fastening, stabilizing and positioning elements for movable or stationary structural parts of devices. Spring pins are used in fixed and movable pin connections. They can connect bushings and shafts in many types of machines. Rolled from a spring steel tape, they are used to transfer impact loads.

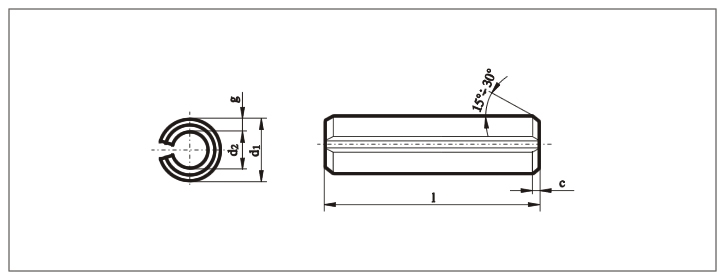

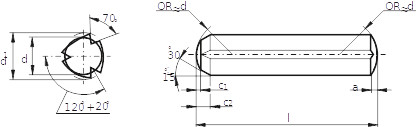

Half-length taper notched pins

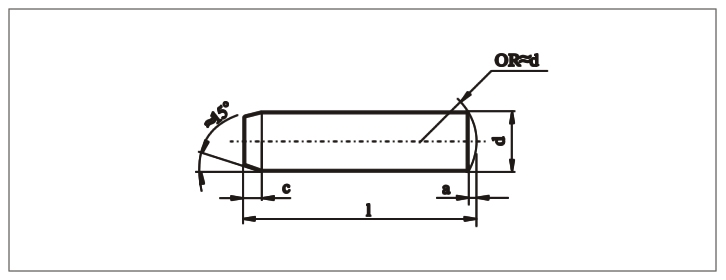

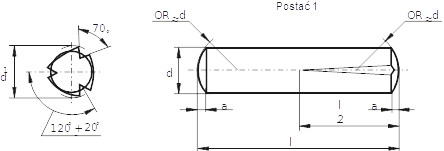

Full length notched pins

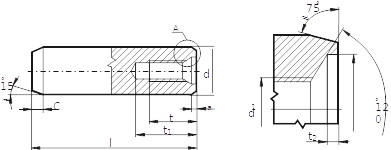

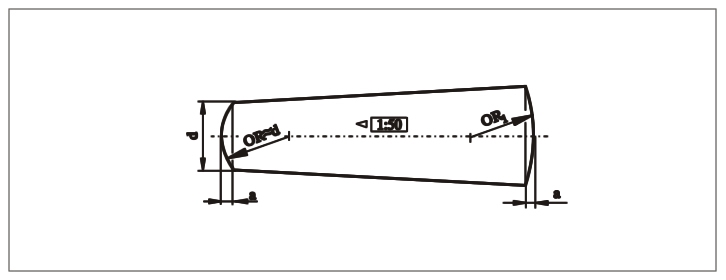

Conical pins with threaded point

Conical pins with internal thread

Cylindrical pins with internal thread